Products

Flexography

Plate Sleeve, Bridge Sleeve (Carrier), Ultra-Thin Sleeves, and Lightweight Cylinder made of composite material with or without shaft, are the main products we offer for this printing system.

Cylitec has developed an alveolar system design for the thicker sleeves and bridge sleeves enabling ultra lightweight products without compromising the excellent mechanical and dynamic properties as well as the dimensional stability required by these critical flexographic products; thus getting the desired printing quality at high-speed manufacturing process.

EPOCYL LINE

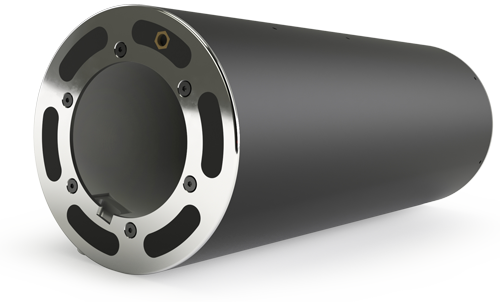

EPOCYL – plate sleeve

Plate Sleeve made of epoxy-based composite.

Resistant to aggressive solvents and high dimensional stability.

Main Properties:

- Resistance to aggressive solvents. Completely encapsulated, it avoids the absorption of solvents and moisture.

- The exclusive alveolar structure confers the product an optimum balance between strength, stability and low weight.

- Side faces protected by anti-impact material.

- Suitable for high speed Printing.

- Surface that enables an optimal adhesion as well as an easy removal of the tape after printing.

- Metal notch from 6mm-thickness.

- Internal protection (optional): Metal protective ring on the notch side to avoid internal damages for thicknesses > 12 mm.

- Warranty: One year against manufacturing defects.

EPOCYL – bridge sleeve

Bridge sleeve made of epoxy-based composite material.

Excellent dimensional stability and very low weight due to the alveolar design developed to deal with high thicknesses.

Main Properties:

- Optimum distribution of surface air allowing easy mounting/dismounting of the sleeves.

- Resistance to aggressive solvents. Completely encapsulated, it avoids the absorption of solvents and moisture.

- The exclusive alveolar structure confers the product an optimum balance between strength, stability and low weight.

- Lateral sides protected by anti-impact material.

- Suitable for high speed Printing.

- Smooth mounting and excellent mandrel hold.

- Internal Protection: Metal protective ring on the notch side to avoid internal damages.

- Warranty: One year against manufacturing defects.

STATCYL LINE

STATCYL – conductive plate sleeve

Plate Sleeve made of epoxy-based composite and electrostatic conductive carbon.

Resistant to aggressive solvents and high dimensional stability.

Main Properties:

- Resistance to aggressive solvents. Completely encapsulated, it avoids the absorption of solvents and moisture.

- Coated with carbon-based material the enables a right static electricity generated during printing process.

- The exclusive alveolar structure confers the product an optimum balance between strength, stability and low weight.

- Lateral sides protected by anti-impact material.

- Suitable for high speed Printing.

- Surface that enables an optimal adhesion as well as an easy removal of the tape after printing

- Metal notch from 6mm-thickness.

- Internal protection (optional): Metal protective ring on the notch side to avoid internal damages for thicknesses > 12 mm.

- Warranty: One year against manufacturing defects.

STATCYL – conductive bridge sleeve

Bridge Sleeve made of epoxy-based composite material and static conductive carbon.

Excellent dimensional stability and very low weight due to the alveolar design developed to deal with great thicknesses.

Main Properties:

- This product, used together with Statcyl Sleeves, allows a right static electricity discharge that is generated during printing process.

- Resistance to aggressive solvents. Completely encapsulated, it avoids the absorption of solvents and moisture.

- Conductive coating made of epoxy-based carbon to allow electrostatic discharge.

- The exclusive alveolar structure confers the product an optimum balance between strength, stability and low weight.

- Lateral sides protected by anti-impact material.

- Suitable for high speed Printing.

- Smooth mounting and excellent mandrel hold.

- Optimum distribution of surface air allowing easy mounting/dismounting of the sleeves.

- Internal Protection: Metal protective ring on the notch side to avoid internal damages.

- Warranty: One year against manufacturing defects.

CARBOCYL LINE

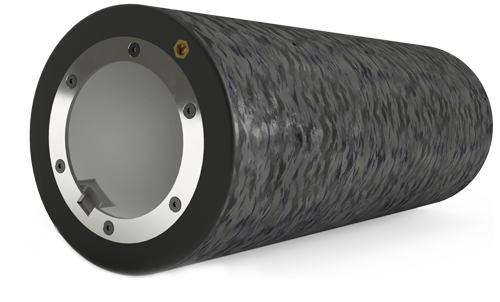

CARBOCYL MIX – bridge sleeve

Bridge Sleeve made of carbon fiber, fiberglass, epoxy-based composite materials.

Excellent dimensional stability and very low weight due to the alveolar design developed to deal with great thicknesses.

Main Properties:

- Optimized version of Statcyl Bridge Sleeve with improvements in the conductivity of the static electricity. This product, used together with Statcyl Sleeves, allows an excellent static electricity discharge that is generated during printing process.

- Resistance to aggressive solvents. Completely encapsulated, it avoids the absorption of solvents and moisture.

- The exclusive alveolar structure confers the product an optimum balance between strength, stability and low weight.

- Optimum distribution of surface air allowing easy mounting/dismounting of the sleeves.

- Suitable for high speed Printing.

- Smooth mounting and excellent mandrel hold.

- The protective ring on both sides not only prevents damages on the flexible central tube caused by the mandrel pin during mounting, but also confers a powerful protection to the Bridge Sleeve ends ensuring a longer life and avoiding damages due to careless handling.

- Warranty: One year against manufacturing defects.

CARBOCYL PREMIUM – bridge sleeve

Bridge Sleeve made of carbon fiber and epoxy-based resins.

Due to the exceptional properties of the carbon fiber, CARBOCYL sleeve offers the lowest weight of its kind, excellent mechanical properties, dimensional stability and high conductivity of the static electricity.

Main Properties:

- Optimal discharge of static electricity due to the excellent conductive propierties of the carbon fiber.

- Carbocyl has the lowest weight of its kind, and excellent dimensional stability, preserving its precise measures for longer.

- Resistance to aggressive solvents. Completely encapsulated, it avoids the absorption of solvents and moisture.

- The exclusive alveolar structure confers the product an optimum balance between strength, stability and low weight.

- Internal Protection: Metal protective ring on the notch side to avoid internal damages.

- Lateral sides protected by anti-impact material.

- Suitable for high speed printing.

- Smooth mounting and excellent mandrel hold.

- Optimum distribution of surface air allowing easy mounting/dismounting of the sleeves.

- Warranty: One year against manufacturing defects.

ELASTOMER LINE

PRINTCYL – direct printing sleeve

Flexible sleeve for continuous printing.

Cylindrical core made of epoxy-based and elastomer coated fiberglass.

Surface treatment to ensure a proper ink application.

Main Properties:

- Good resistance to aggressive solvents.

- Smooth mounting and excellent mandrel hold.

- Suitable for high speed Printing.

- High resilience.

- Ozone resistant.

- Antistatic properties.

- Warranty: One year against manufacturing defects.

FLEXCYL – Sleeve for adhesive application

Elastomer coated sleeve for lamination processes.

Conical core made of epoxy-based fiberglass, coated with elastomers specifically formulated for application of mono and two-component adhesive.

Main Properties:

- Good resistance to aggressive solvents.

- Smooth mounting and excellent mandrel hold.

- High resilience.

- Ozone resistant.

- Antistatic properties.

- Warranty: One year against manufacturing defects.

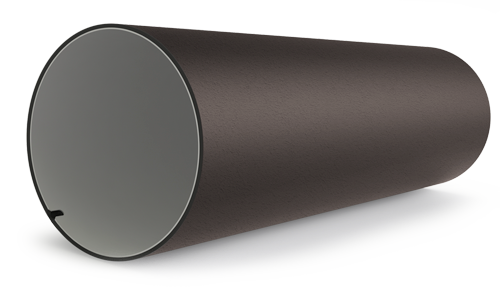

COMPRECYL – Compressible surface sleeve

Elastomer coated sleeves with different hardness to be used with double-sided tape 0.1 mm thick. Cylindrical core made of epoxy-based fiberglass.

Main Properties:

- Good resistance to aggressive solvents.

- Smooth mounting and excellent mandrel hold.

- Suitable for high speed Printing.

- High resilience.

- Ozone resistant.

- Antistatic properties.

- Warranty: One year against manufacturing defects.

MANDREL WITH AXIS

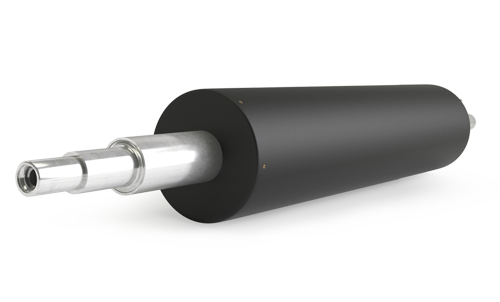

LIGHTWEIGHT AIR MANDREL

Lightweight Air Mandrel made of epoxy-based composite materials to be used as a sleeve holder.

Used in conventional flexo machines replacing the heavy steel cylinders.

Main Properties:

- Aggressive Solvents Resistance. Completely encapsulated, it avoids the absorption of solvents and moisture.

- The exclusive alveolar structure confers the product an optimum balance between strength, stability and low weight.

- Suitable for high speed printing.

- Optimum distribution of the surface air that allows easy mounting/dismounting of the sleeves.

- Warranty: One year against manufacturing defects.

ANILOX COVER

COVERCYL – anilox cover

Flexible Anilox cover with smooth interior.

Main Properties:

- Cover made of resistant material and soft inside.

- Rubber diaphragm to efficiently attach the cover to the anilox.

- Provided with a label with information on the anilox to be protected.

- Warranty: One year against manufacturing defects.